[ad_1]

The 140-year-old Hunedoara Iron Works was transformed in the 1950s into one of the largest steel mills in Eastern Europe.

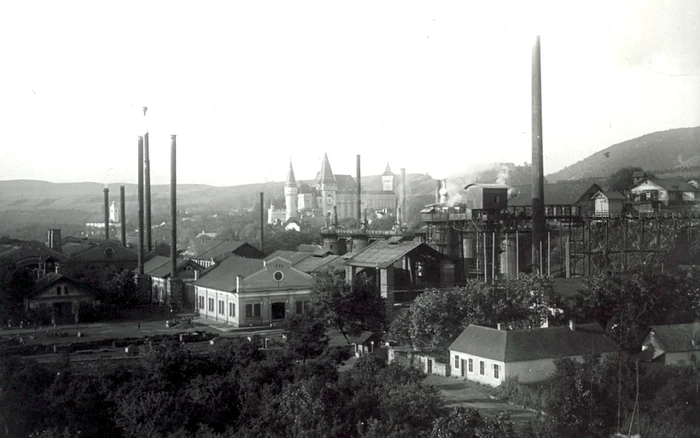

Hunedoara Steel Works in the 1900s. Shoch Flegus

Several historic buildings near Covinillo Castle were built more than a century ago and have survived the passage of time at the Hunedoara Iron and Steel Works. The metallurgical centre was established more than 140 years ago, with the first furnace in Hunedoara being inaugurated in the summer of 1884.

140th Anniversary of the Ironworks

Meanwhile, thousands of locals in the town at the foot of Corvinilor Castle were celebrating the opening of the Hunedoara-Cimmeria Railway, a branch of the Transylvanian Railway line Alba Iulia-Deva-Arad, and of Corvinilor Castle, destroyed in a fire in 1854.

Image 1/14:

Ironworks

Since 1900, another railway (Hunedoara – Ghelari) has connected the Hunedoara Iron Works with the iron ore mining areas in the Boyana Ruska Mountains (video).

“Bless Hunedoara, wish him good luck! The first cast iron has flowed, Hunedoara’s Geraliu Mountain is melting. This great event is not characterized by celebrations and pompous speeches, but by black smoke from chimneys throughout the region, announcing a joyful news: a better future is no longer a dream, a future for Hunedoara and its surroundings that they have been waiting for many years, even in the last years they have been looking forward to with fear. And those wonderful iron birds (not the chimneys of the cable car) have been circling in the air for some time… The beginning of the work loudly praised the construction engineers”In 1884, the weekly Hunyad reported.

Construction of the first furnace in Hunedoara began in 1882. The Franciscan monastery and several local residents donated land to the state to make the investment possible. The first furnace began operating in 1884, and the second furnace opened a year later.

By 1902, the Hunedoara plant had five furnaces built, and by 1906, 46 furnaces were in operation, processing ore from Gairari (video), for the production of iron and cast iron, and within a few years for the production of steel (1892-1904).

In 1887, Emperor Franz Joseph visited the Hunedoara furnaces, an event commemorated by a triumphal arch erected at the factory entrance. The base of the arch is made of iron ore and limestone fragments used in the ironworks, as well as cast iron plates and slag piles from Hunedoara’s two furnaces.

“From this base the grid of columns of the triumphal arch rose into the sky, made of thin square profiles and thin flat iron, with two huge masts on which hung two national flags. The base of the columns was surrounded by the products of the ironworks, and in the middle of the columns were placed the coats of arms of Transylvania and Hungary and the monogram of the king, surrounded by decorations of national flags,” Vasarnapi Ujesag” (The Sunday Times), Budapest, 1887.

The five furnaces of Hunedoara and the furnace of Govăjdia (Video) They processed the ore from Ghelari, which was extracted from a mine about 20 km away. At the beginning of the 20th century, the pig iron obtained was supplied to the factories in Kujir and also to some Hungarian steel mills. The furnaces built for the production of steel were replaced, and their activities were considered unprofitable.

Before World War I, more than 2,500 people worked at the Hunedoara Steel Works. After the Grand Union of 1918, the factories were taken over by the Romanian government and managed by the Mining Directorate.

“At that time, the Hunedoara Mining and Iron and Steel Complex had a considerable mining capital: iron ore mining in Gherar, Aranjes, Vadurdobri (Hunedoara County); mining concessions in Lunca Cernii, Alun (Hunedoara County), Sălciua de Jos, Trascău, Runc (Turda-Aries County) and Bodvai (Odorhay County); five blast furnaces with an annual output of 119,000 tons, a foundry with an annual output of 1,500 tons; a forging plant equipped with two steam hammers; a mechanical workshop with an annual output of 500-600 tons of castings and forgings; a production workshop with an annual output of 1,200,000 clay bricks””, points out Ludovic Bathory in his study “The State Iron Works in Hunedoara, 1919-1940”.

The raw materials for these factories came from the limestone quarries in Bunila and from the numerous coal-fired plants in the Padureñillo area, which produced the charcoal needed for the furnaces. They had a hydroelectric power plant, a mill, and several cable cars for transporting ore.

In Gowaidiavideo), an old blast furnace from the early 19th century and a water hammer plant are in operation.

However, the deterioration of equipment at many of the factories and the lack of raw materials led to the closure of the Govaidiyya furnace and four of the five furnaces in Hunedoara in the 1920s, and the decline of iron production in Hunedoara.

Romanian state investments in the development of the Hunedoara Iron Works began to bear fruit in the 1930s, when the city of about 7,000 inhabitants once again became one of Romania’s important metallurgical centers.

Ironworks transformed into steel complexes

In the 1950s, the old factory was transformed into a steel complex covering an area larger than Hunedoara.

In the 1970s, about 20,000 people worked here. Annual crude steel production reached more than 3 million tons. Then there was the steel plant in Hunedoara, which was one of the best performing industrial centers in Romania at the time. Annual production was nearly 2 million tons of cast iron, about 3 million tons of steel, 1 million tons of metallurgical coke, and more than 2 million tons of rolled products and other metallurgical products, which were considerable quantities at the time.

“The Hunedoara Iron and Steel Complex covers an area of 430 hectares, with two areas and six furnaces in operation; three steelmaking plants – 13 Martin furnaces and 6 electric furnaces; in full bloom. And this is only part of it.”, said the publicist Mircea Bunea (1938-2012) in Scânteia (January 28, 1972).

Also in the 1970s, the population of Hunedoara had reached about 80,000 people, and almost every family had at least one employee in a joint venture or construction company (ICSH) in Hunedoara.

Hunedoara Steel Plant, in decline

From the early 90s, Combine Harvester (which later became Siderurgica Hunedoara) began to shut down parts of it that were deemed unviable, starting with the old Siemens Martin steelworks, which closed in 1991. With the reduction in activity, a wave of employee layoffs also began.

The Hunedoara Steelworks were privatized in 2003 following a series of restructurings that began in the mid-1990s, leading to a phased reduction in the number of employees from nearly 20,000 in 1991 to around 2,500 in 2004. The plants were taken over by the current ArcelorMittal Group.

At the same time, much production capacity deemed unviable, including Siemens Martin steelworks, coke plants, briquette plants and blast furnaces, has been closed, decommissioned and dismantled since the 1990s.

Twenty years after the Romanian government privatized and sold the Hunedoara Steel Plant, a small part of the former industrial giant survives following the massive demolition of the plant.

In the 2000s, a wave of layoffs overlapped with a massive demolition of the old steel platforms in Hunedoara, leaving behind ruins instead of huge concrete buildings.

ArcelorMittal’s Hunedoara plant still has about 600 employees and has produced about 200,000 tons of crude steel per year in recent years.

[ad_2]

Source link